To improve the reliability of the equipment in the factory, the analysis and early diagnosis of equipment status is an indispensable need. However, when implementing this solution, it is necessary to have a high-tech solution, intensively trained processes and people, leading to a very large initial investment cost and a long time to bring it up. system into operation. Understanding this, S5T provides rM&D – SmartSignal diagnostic analysis service based on the world’s leading technology platform of GE Digital. This is the solution that helps to prevent the maximum damage to the plant, increase the reliability of the equipment, and at the same time increase the operating efficiency.

Technology platform used for rM&D diagnostic analysis service – SmartSignal

SmartSignal works by analyzing all available measurements on the device to detect potential problems. Simultaneously signal the potential for errors, localize, diagnose, prioritize, and generate incident reports. Situations will be handled on an ad-hoc basis and the modeling automatically adapts over time.

Working principle of SmartSignal system

Outstanding advantages of rM&D diagnostic technology – SmartSignal

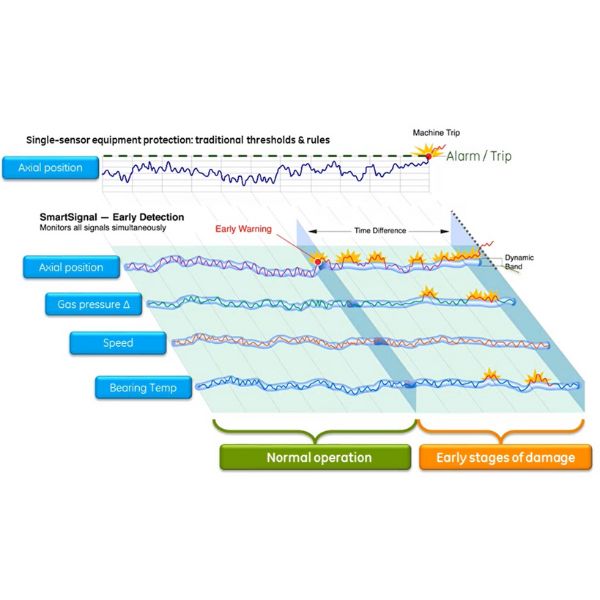

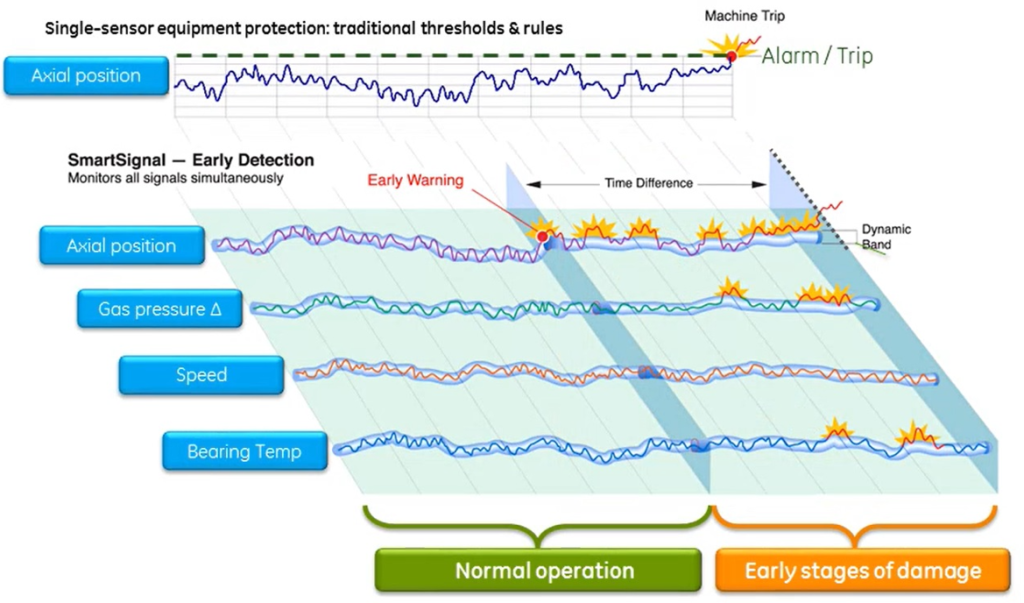

The traditional solution uses each sensor individually for device monitoring, and an alarm is only raised if the signal exceeds the fixed thresholds configured in the DCS system; SmartSignal works more efficiently by monitoring signals from sensors simultaneously. SmartSignal is based on historical data, the corresponding mode, the system will calculate the desired value of the signal at the current time based on the SBM algorithm (similarity-based modeling). This value will be compared with the actual value received through the sensors. When the difference between the actual value and the calculated value exceeds the allowed dynamic band, the system will give early warnings to the operator.

An early warning is given if the following factors are satisfied such as the equipment is operating, there is a significant deviation between the actual signal from the sensor and the calculated value from the model, the deviation lasts for a period of time. time is large enough, and eventually must match a pattern of problems.

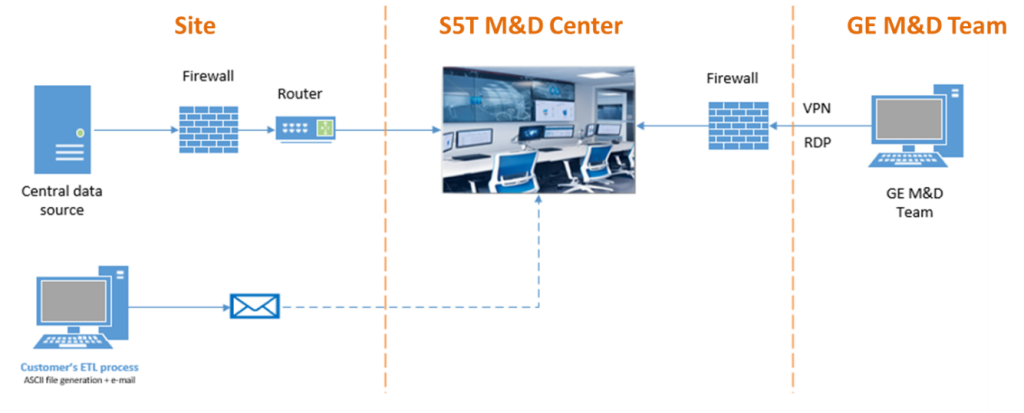

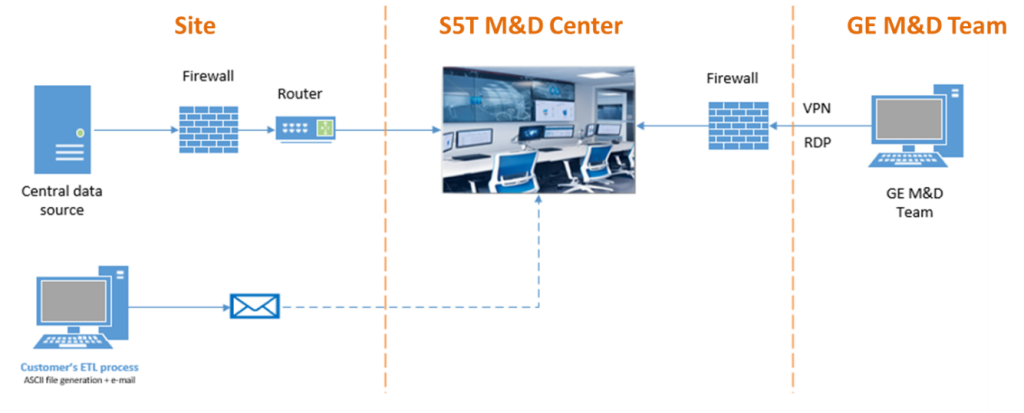

Architectural diagram of SmartSignal . solution

Components in the SmartSignal system

- At the factory: Equipped with computers to collect data from DCS and Data Historian systems and send it to S5T’s rM&D center, information security devices such as FW, Router.

- At the center: Equipped with diagnostic analysis servers, FW security devices, Routers.

How to deploy rM&D diagnostic analysis service to factories

- S5T and GE’s remote diagnostics and monitoring teams use early detection and analysis of potential equipment failures through artificial intelligence, machine learning, and digital twin modeling.

- The devices will collect and analyze data from available sensors, then the data will be sent to the rM&D center located at S5T.

- Experts will detect and provide recommendations to the plant periodically, or immediately when abnormalities are detected.

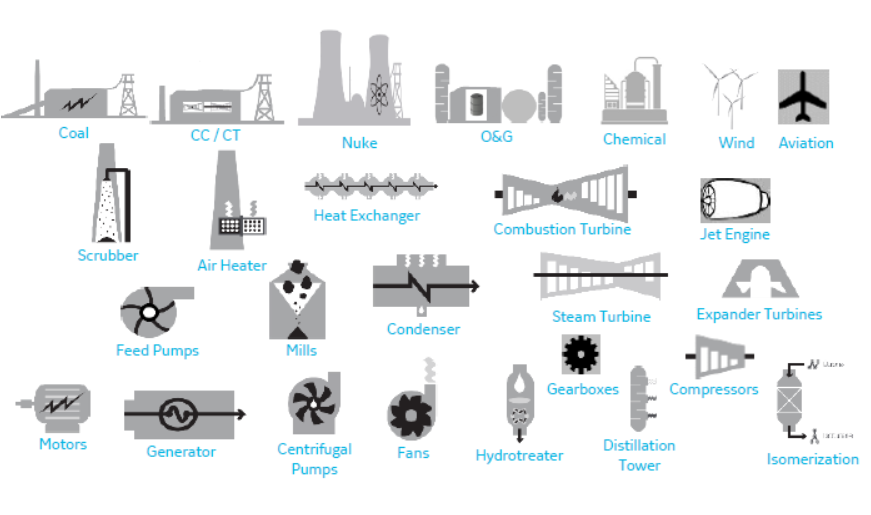

Applications of early diagnostic analysis solutions for industries

With over 300 digital replica models built for GE equipment and various vendors. The solution can be applied to a variety of industries such as: energy (generating plants including hydroelectricity, thermal power), oil refineries, chemical plants, steel mills, etc. Typical equipments are shown below. Monitoring in the factory includes: turbines, generators, transformers, compressors, feed pumps, fans, engines, crushers, boilers…

Applications of early diagnostic analysis solutions for industries

Effective use of S5T rM&D diagnostic analysis service

S5T service will enable factories to take the next step in analysis and diagnostics by answering the following questions:

- What problems will happen to the factory equipment?

- What are the causes of the incidents?

- What is the priority, severity of the impending incident?

- What is the estimated time to repair the device?

In addition, the solution also brings economic efficiency, helping businesses optimize production:

- Low upfront investment, use on an annual subscription basis.

- Take advantage of the in-depth knowledge of GE, S5T, without wasting too much time and money on in-house professional training.

- Bring efficiency in short time (short time-to-value).

Thus, S5T’s service helps the factory’s human resources to focus on proactive and economical troubleshooting, rather than waiting and looking for repair. This is the premise to help the plant move towards the most advanced maintenance level such as RCM reliability maintenance. Specific metrics and benefits of rM&D diagnostic analysis services include:

In terms of equipment:

- Phát hiện sớm các lỗi tiềm ẩn, do đó ngăn chặn chúng tiến triển xấu đi.

- Cải thiện độ tin cậy và tính sẵn sàng.

- Cải thiện hiệu quả.

In terms of process:

- Switch to active instead of passive.

- Optimizing maintenance and repair activities.

- Make a repair plan before the fault occurs.

RM&D diagnostic analysis service implementation process

Step 1: Survey, design hardware and software for the system.

Step 2: Collect factory data (P&ID, tag list, alarm limits, etc…).

Step 3: Install the software.

Step 4: Configure SmartSignal system.

Step 5: Initialize the Assets (main devices) of the factory.

Step 6: Build the initial database.

Step 7: Model, test and calibrate the system at rM&D S5T center.

Step 8: Test run, evaluate the quality.

Step 9: Put into official operation.

Step 10: Periodic report to the factory.

Professional competence and practical experiences of S5T

S5T is currently the only partner in Vietnam of GE Digital – a leading unit in analysis and early diagnosis of equipment status. With in-depth knowledge and practical capacity, we will help customers get the most effective, economical and optimal solution:

- Helps increase productivity, optimize operating costs, and increase equipment reliability.

- Ready to support 24/7 in the form of direct support, remote consulting (website, phone support).

- Professional working process from consultation, design, installation, transfer, support to after-purchase customer care.

Để biết thêm thông tin chi tiết về dịch vụ phân tích chẩn đoán sớm rM&D, vui lòng gửi yêu cầu vào hộp thư, hoặc liên hệ với chúng tôi theo địa chỉ dưới đây để nhận tư vấn chuyên môn:

Địa chỉ: Công ty CP Công nghệ và giải pháp S5T Việt Nam.

Lô B15, Khu tái định cư Dương Nội, Dương Nội, Hà Đông, Hà Nội.

Tel: 0243 540 1858 – Fax: 0243 540 1859

Email: info@s5t.com.vn