Currently, monitoring of partial discharge in insulation has become an essential need for reliable and stable operation to optimize production for factories. However, fully equipping the entire solution and mastering technology requires large capital and time, which is considered unfeasible and causes difficulties for some units. Therefore, choosing to use PD partial discharge analysis service of S5T Vietnam Technology and Solution Joint Stock Company is the first choice. Because customers only need to spend very little, but still get detailed data analysis reports for the PD condition happening inside the device.

Partial discharge analysis service PD

Partial discharge analysis service overview

- Service name: Partial discharge data collection and analysis in stator winding insulation.

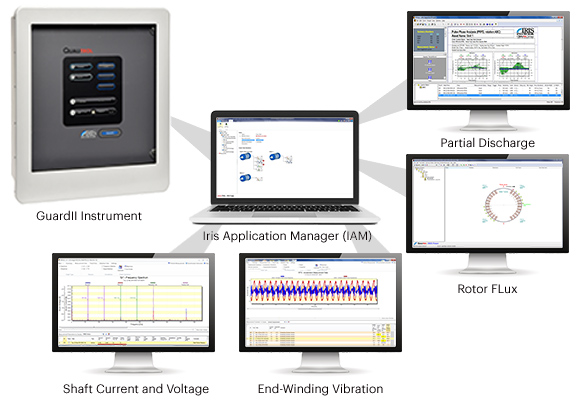

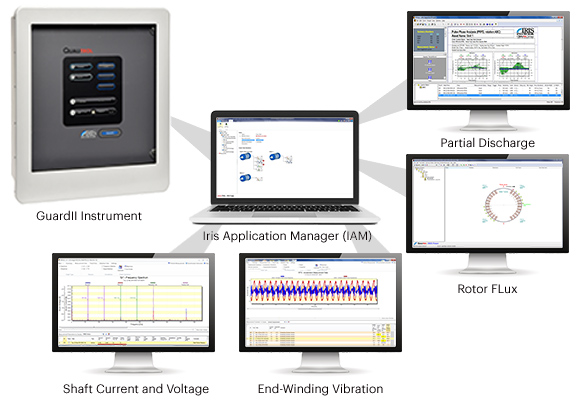

- Equipment used: EMC- 80 pF condenser sensor, data collector: PDA-IV.

- Time frame: sensor installation service can be performed during the annual downtime for repair. Once the sensor is installed, the data can be retrieved at any time while the device is running online.

- Human resources: Hardware installation: 04 people, 01 engineer trained from IRIS POWER; Data collection: 01 engineer trained from IRIS POWER.

- Scope of application: the service can be used for generators (hydroelectricity, thermal power, …), important medium voltage engines in power plants and industry.

- Parameters used to monitor: technical parameters used to evaluate PD status in insulation such as +Qm, -Qm, +NQN, -NQN, number of pulses per second (pps), pulse amplitude, phase angle …

- Data analysis results report: issued by experts with genuine training certificates from IRIS POWER, with many years of experience and with the support of a team of experts from the company.

Benefits of partial discharge analysis in insulation

Online partial discharge monitoring is the collection of partial discharge impulses occurring in the internal and surface voids of the winding insulation. Through analyzing the collected data, it is concluded that partial discharge is taking place and propose solutions to repair and maintain with insulation if necessary. This creates the basis for annual equipment repair and maintenance decisions, in order to improve equipment life, stable production operation and save repair costs.

Benefits of device PD analysis:

- Preventing electrical discharges that damage insulation, leading to serious problems for generators and medium voltage electric motors.

- Helps increase machine reliability.

- Save on repair costs.

- It can be done while the machine is running, so it is possible to collect and find the root cause of the problem, without affecting revenue interruption, and optimizing the factory’s production process.

Application of partial discharge analysis service PD for equipment

The PD analysis service is applicable to the detection of insulation damage in the stator of rotating machines of the following industries:

- Hydroelectric.

- Thermal.

- Wind electricity.

- Other industry.

Partial discharge analysis service packages S5T

S5T Vietnam Technology and Solutions Joint Stock Company provides service packages related to partial discharge monitoring solutions as follows:

- Online PD data collection and in-depth periodic analysis of PD condition for generator winding insulation.

- Online PD data collection and in-depth periodic analysis of PD conditions for winding insulation of medium voltage motors.

PD analysis service implementation process

Step 1: Receive the requested information from the customer.

Step 2: Stop the machine to survey the status quo to make a construction plan.

Step 3: Stop the machine during the repair period.

Step 4: Install the sensor and hardware system.

Step 5: Calibrate the system.

Step 6: Get on the machine and proceed to collect PD pulse data.

Step 7: Send PD data to IRIS POWER for analysis and release report on ongoing partial discharge.

Why choose S5T PD partial discharge analysis service?

S5T is currently the only dealer in Vietnam authorized to distribute PD surveillance systems provided by Iris Power. We are proud that individuals, organizations and businesses have the ability to bring the best value to customers:

- S5T owns a team of experienced and knowledgeable experts who have participated in many practical projects to install PD systems such as: installing a continuous online monitoring system at Dong Nai 4 Hydropower Plant. , the periodic PD data collection, monitoring and analysis system project at Air Liquid Vietnam, and many others).

- Iris Power’s high technology application is the most prestigious and advanced in the world in the field of PD monitoring today.

- Helps increase efficiency, optimize production costs, and increase reliability for thermoelectric generators and engines being monitored.

- The team of S5T engineers and Iris Power’s leading experts in PD analysis are always following the process, ready to support customers anytime, anywhere: remote support, live support.

- Professional working process from consultation, design, installation, transfer, support to after-purchase customer care.

For detailed advice on PD partial discharge analysis services suitable for plants, equipment… Please connect with us by sending inquiry to mailbox, or contact via the following address:

- Address: S5T Vietnam Technology and Solution Joint Stock Company.

- Lot B15, Duong Noi Resettlement Area, Duong Noi, Ha Dong, Hanoi.

- Tel: 0243 540 1858 – Fax: 0243 540 1859

- Email: info@s5t.com.vn