In the inevitable development trend, advanced factories in the world as well as in Vietnam are aiming for stable, reliable and efficient operation at the highest level. Therefore, PD partial discharge monitoring for hydroelectric generators becomes a very important need and is the number one priority today.

Significance of installing partial discharge monitoring system for hydroelectric generator

PD Partial Discharge Monitoring System is used to monitor insulation on GIS, transformers, camcorders, motors, cables or other high voltage equipment. For transmitters, the tools in the PD system are designed to record long-term data, handle alarms, recognize events, integrate a continuous transmitter monitoring system over time, and at the same time Plan maintenance and prevent machine breakdown effectively.

Benefits of installing a PD monitoring and analysis solution for hydroelectric generators:

- Monitor, collect and analyze PD data at any time during the operation period and the equipment is still operating normally.

- Record PD over time, build PD development trends, and provide early warnings for possible impending incidents in time.

- Facilitating equipment maintenance according to the actual condition of the machine to save maintenance and repair costs, ensuring high reliability, stability and continuous operation.

Components of the PD system for installation of hydroelectric generators

+ Hardware

The set of machinery and equipment for installing PD systems for hydroelectric generators includes:

- Sensor EMCs – 80 pF.

- Data Collector PDA-IV.

Sensor EMCs – 80 pF

Data Collector PDA-IV

+ Software

The PD View and IAM software receive data from the measuring device, then analyze and report the PD status in the stator winding with high accuracy.

+ Service

The service collects and analyzes PD data periodically with a frequency depending on the actual condition of the hydroelectric generator being monitored.

Installation process of periodic PD monitoring system PDA-IV

Step 1: Survey and determine the installation location of EMCs sensors, junction boxes.

Step 2: Make a construction plan to install the equipment at the surveyed locations.

Step 3: Connect and calibrate the signal, ensuring it is correct according to the company’s noise filtering technology.

Step 4: Get data from the junction box to the PDA-IV collection device, connect it to a computer that has installed its specialized software to provide PD analysis.

Why should you choose to install Iris Power’s PDA-IV periodic PD partial discharge monitoring system provided by S5T?

Why choose Iris Power’s PD monitoring solution?

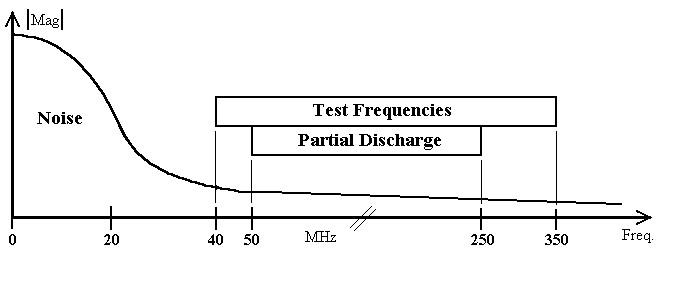

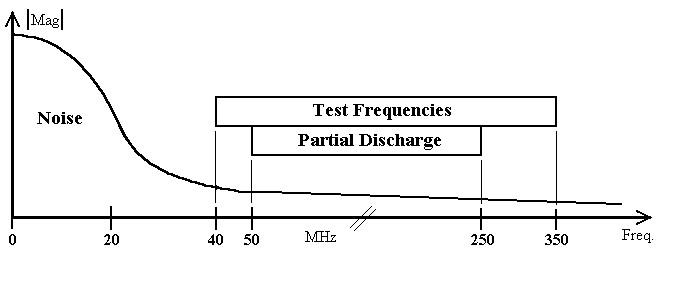

During PD monitoring, there are a lot of noise signals coming from many sources, which can be from inside the transmitter, or also from outside the system, so PD analysis becomes very difficult. Therefore, noise separation filtering technology when monitoring and analyzing data about PDs of brands becomes a separate quality and value standard.

For hydroelectric generators, based on the geometry and structure of the stator windings, it is possible to choose to use solutions for continuous online PD monitoring, periodic online, using one or a combination of capacitor type sensors. together, combined with a dedicated high-tech data acquisition device that can eliminate most types of interference and retain only the PD signal for machine condition analysis. The characteristic of the PD pulse is that the surge time current pulse is particularly fast and lies mainly in the frequency range of 50 – 250 MHz. The large, high amplitude noises are all located in the frequency range below 20MHz.

Iris Power specializes in researching and applying leading and famous PD Online and Offline monitoring solutions around the world. Applied to a PD monitoring solution, Iris Power designs and manufactures sensors (Epoxy-Mica Capacitors – EMCs) and measuring instruments (PDA-IV) that can successfully remove interference from PD pulses efficiently. And especially, users can perform PD test, analyze results quickly after only 2 days of training.

Diagram depicting the operation of the PD . pulse

Why should you choose the installation service of PD partial discharge monitoring solution provided by S5T?

S5T is currently the only dealer in Vietnam authorized to distribute PD surveillance systems provided by Iris Power. We are proud that individuals, organizations and businesses all have the experience and capacity to bring the best values to customers:

- S5T owns a team of experienced and knowledgeable experts who have participated in many practical projects to install PD systems such as: installing a continuous online monitoring system at Dong Nai 4 Hydropower Plant. , the periodic PD data collection, monitoring and analysis system project at Air Liquid Vietnam, and many others).

- Iris Power’s high technology application is the most prestigious and advanced in the world in the field of PD monitoring today.

- Helps increase efficiency, optimize production costs, and increase reliability for hydroelectric generators being monitored.

- A team of well-trained, experienced S5T engineers, accompanied by Iris Power’s leading experts in PD analysis, always follow the process closely, ready to support anytime, anywhere: remote support , direct support.

- Professional working process from consultation, design, installation, transfer, support to after-purchase customer care.

For detailed advice on each periodic PD online partial discharge monitoring solution suitable for plants and equipment… Please connect with us by sending a request to the mailbox, or contact us via after:

- Address: S5T Vietnam Technology and Solution Joint Stock Company.

- Lot B15, Duong Noi Resettlement Area, Duong Noi, Ha Dong, Hanoi.

- Tel: 0243 540 1858 – Fax: 0243 540 1859

- Email: info@s5t.com.vn