S5T is a DCS solution integrator for hydropower plants based on Nexus Controls – GE’s Oncore platform. With a team of experienced professionals, we are completely autonomous in surveying, designing, constructing, installing, and calibrating the system, as well as conducting training courses for customers. Thus, helping businesses save costs, optimize operations, increase production efficiency.

DCS solution of hydropower plant

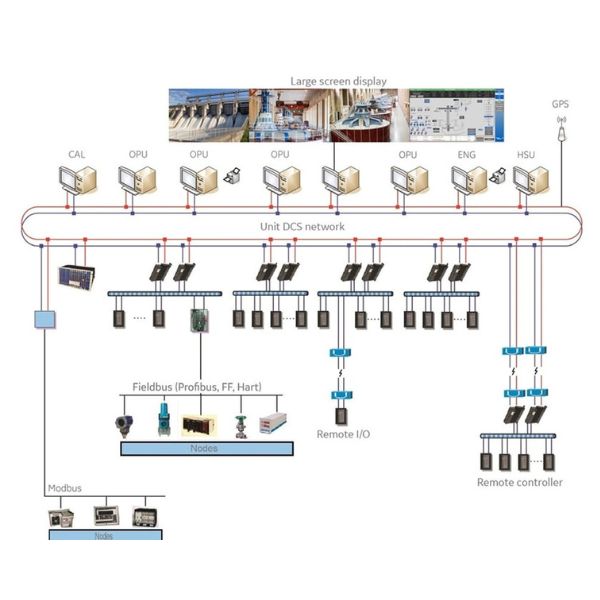

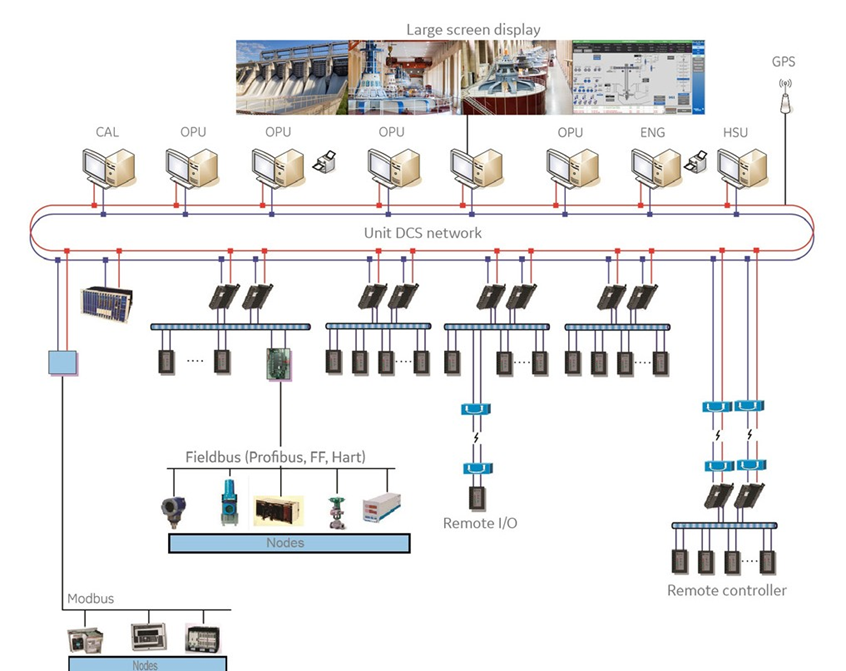

The OnCore control system for hydropower plants is integrated in the same hardware and software platform with the following control functions:

- Engine control.

- Control of auxiliary systems (water intake, compressed air system, cooling system, turbine monitoring devices, generator…).

- Control power distribution stations.

- Control the overflow gate.

- Generator and transformer protection interface.

- Magnetic system interface.

- Transformer system interface.

- Connection to moderation levels.

Typical Oncore control system with redundant network

Components of the DCS solution in a hydro power plant

System software DCS

The OnCore control system offers an integrated OptimumC comprehensive software package that enables visualizations, logs, graphics and alarms to give operators a complete view of the plant and its assets – This helps provide a clear picture for data analysis and troubleshooting.

OptimumC control software supports powerful control applications through simple configuration of function blocks, so it is easy to learn and use. In addition, real-time (online) and offline configuration execution is also integrated for monitoring convenience. Functionally, the process control capabilities of OptimumC software include:

- Collect data.

- Continuous control.

- Logic control.

System Hardware DCS

At the heart of the OnCore control system is the iDPU controller, which is a standalone, integrated computer that runs application code for control and data transmission. iDPU communicates with process I/O modules and can be implemented in a redundant configuration.

- Some other hardware includes:

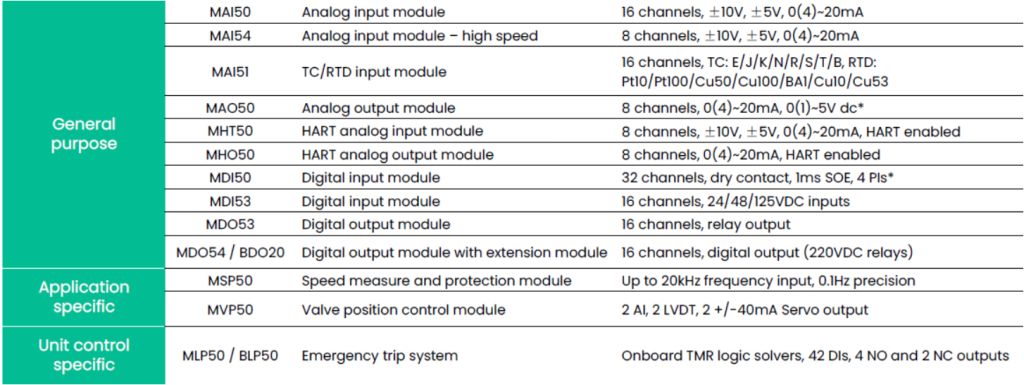

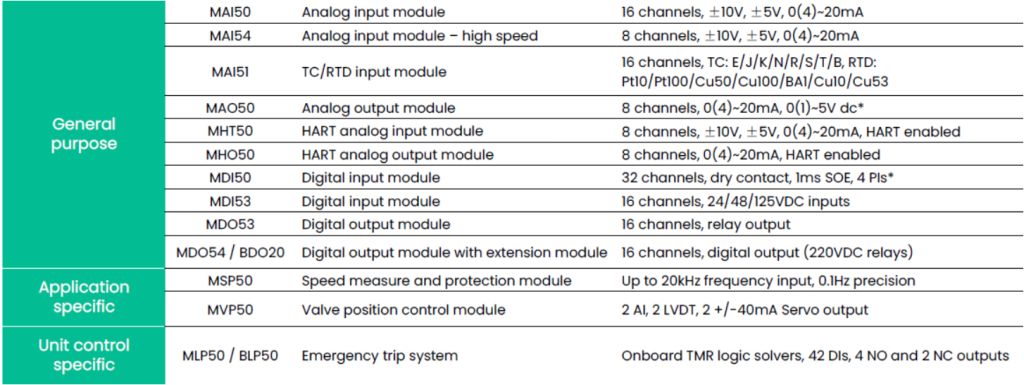

- Input and output modules:

Input and output modules

- Operation station, technical station, historical data storage station.

Why should DCS solution be set up for hydropower plants?

Why should install DCS system for hydro power plant?

DCS systems are especially essential in high-volume manufacturing operations. Meanwhile, with few human resources, humans cannot manually monitor many individual systems, but an automated central facility is required. Therefore, the DCS system now plays an important role to:

- Help support production scheduling, preventive maintenance scheduling, and information exchange.

- Help monitor or significantly improve operational features such as: report export, device protection, fault detection, and fault isolation in subsystems to perform repairs.

- Redundant architecture provides enhanced control reliability and uninterrupted system access.

- Features a rich library of function blocks, allowing users to customize application and/or specific sequences to adapt to both current and future power plant configurations.

- DCS configuration software allows users to easily customize the HMI screen, conveniently control and monitor the overall operation of the plant.

The process of deploying the DCS solution installation service of S5T

Step 1: Receive customer requests, survey the system.

Step 2: System design, assembly manufacturing, factory inspection.

Step 3: Dismantle the old system (in case of need to upgrade), install the new system.

Step 4: Configure, install, test the system.

Step 5: Check, test and adjust at the scene.

Step 6: Training, operating instructions.

Step 7: Handover, warranty advice, customer care.Tại sao nên lựa chọn lắp đặt hệ thống DCS của S5T?

Nexus Controls – GE

With over 62 years of experience delivering turbine control system upgrades and inheriting Woodward Governor Hydro’s more than 150-year foundation, Nexus Controls has a deep understanding of hydro plant equipment and systems. . The Nexus Controls DCS system allows the direct integration of excitation, speed, vibration, protection relays and other auxiliary systems into one system to optimize overall home operation. machine.

In addition, Nexus Controls also has a team of very experienced experts in the field of hydropower, committed to supporting customers in the best way. All hardware products, software and services are self-developed and owned by the company, so it ensures long-term support for customers.

S5T staff capacity

- The technical team has extensive experience in DCS system implementation in hydro power plants.

- As an autonomous unit in planning design, construction implementation, Commissionning, FAT, customer training.

- We have experience in deploying and installing DCS system for many large projects in the field of hydropower, typically the project to upgrade the DCS system of unit 4 of Ialy hydroelectric power plant….

- The staff is ready to support customers 24/7 when needed by online/offline forms.

For more detailed information about the DCS solution, please send a request to the mailbox for expert advice. Or you can also contact us at the address below.

- Address: S5T Vietnam Technology and Solution Joint Stock Company.

- Lot B15, Duong Noi Resettlement Area, Duong Noi, Ha Dong, Hanoi.

- Tel: 0243 540 1858 – Fax: 0243 540 1859

- Email: info@s5t.com.vn