The Iris Power RIV 800 robotic inspection vehicle and camera system allows for a visual inspection of the generator stator and rotor, including inspecting the vents for debris, with or without removing the rotor. This kit is an automated means for electromagnetic core defect detection testing such as ELCID and stator wedge analysis testing such as SWA.

What it means to install the RIV800 kit for visual inspection of devices

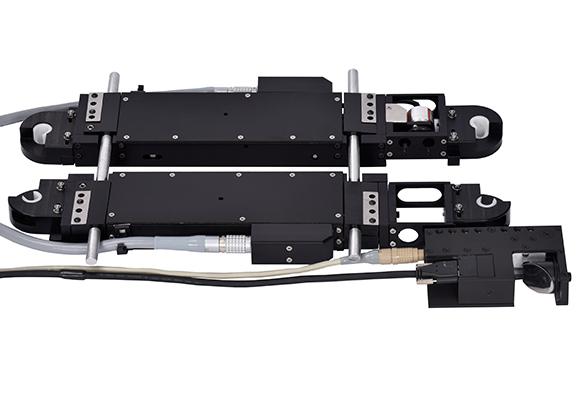

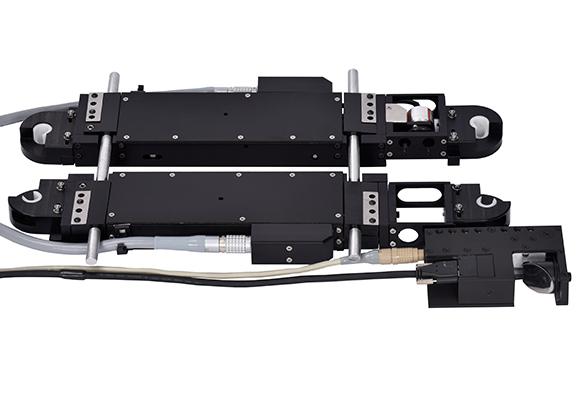

The Magnetic Assisted Robotic Test Vehicle (RIV 800) has been developed to provide an automated scanning method for the ELCID stator core magnetic insulation tester. The kit allows scanning of the stator bore of a generator or large motor to more effectively check the integrity of the stator’s insulation and magnetic coatings.

The device can also be adapted to carry other lightweight accessories for stator testing including: a mini camera, a wedge tightness probe and a single controller used for power and control. controls for vehicle and camera modules.

The Iris Power RIV Camera System provides a flexible system for on-site Roto inspection of large generators. It is fitted to the Iris Power robotic test vehicle that can move along the stator tracks. Built-in light, camera, light directed at the mirror 45° angle, can be rotated remotely to 360° by remote control to scan the stator or rotor as well as looking forward along the air gap are also outstanding advantages of Camera Iris Power RIV.

In addition, the camera can also focus with the remote control. Video output is displayed on the integrated 150 mm color TFT LCD in the control unit. Composite video output will be provided to a second monitor or video recorder.

Benefits of installing RIV800 visual inspection monitoring solution:

- Reduce overall maintenance costs by providing faster testing with just one operator.

- It is possible to test without removing the machine rotor, as long as the clearance is suitable for the device: fit 35mm clearance for on-site rotor testing.

- The guide system detects that the edges of the stator teeth follow a straight line and measures the distance using the encoder wheel. Adjust the curvature to suit the tractor in different sized stator cores. The AUTO mode allows the RIV to stop at a set distance and then only move in the opposite direction, adjusting the speed of change.

- The camera has a wide scanning angle, giving a clear and complete image of the inspected parts such as the stator bore, the integrity of the insulation between the magnetic corrugated board, etc. In addition, the machine can scan the image. while conducting wedge tightness test, visual check for debris in the air gap, built-in dual light source.

Components of the RIV800 system for visual inspection of equipment

+ Hardware

The RIV800 equipment set includes: Remotely controlled moving vehicle along the stator track and a Monitor for monitoring images and collected results.

Moving vehicle with remote control

Monitor images and results collected

+ Service

The service collects image data on cleanliness in the vent holes, tightness/tightness of the inserts, integrity of the insulation between the stator’s magnetic corrugated sheets, from which to analyze and provide reports to have a basis for building maintenance and repair plans with optimal cost and effectiveness.

Procedure for implementing the RIV800 visual device inspection solution

Step 1: Stop the machine.

Step 2: Use a vehicle with a built-in camera to move along the air gap.

Step 3: Collect data about the RIV800, can view the image directly or give it to another screen for better observation.

Step 4: From the collected data, analyze and evaluate the condition of the device after inspection.

Why should you choose to install the Iris Power RIV800 system provided by S5T?

Why choose Iris Power’s RIV800 visual inspection solution?

The device helps customers evaluate cleanliness in the vent holes, tightness and tightness of the cams. In addition, the integrity of the insulation layer between the stator’s magnetic corrugated iron sheets is checked, thereby analyzing and reporting to have a basis for building a cost-effective and effective maintenance and repair plan. Optimal.

Why should you choose the PD system installation service provided by S5T?

S5T is not only an authorized dealer in Vietnam to distribute PD surveillance systems provided by Iris Power, but we are also an enterprise with full capacity and experience to bring customers the best solutions. world today:

- A team of experienced, genuine trained experts with in-depth understanding of partial discharge, experience in construction, installation, configuration, test run and data analysis of PD. Some typical projects we have participated in include: installation of a continuous online monitoring system at Dong Nai 4 Hydropower Plant, the project of Periodic PD data collection, monitoring and analysis system project. at Air Liquid Vietnam, and many other projects).

- Capture, consult and build the optimal solutions for partial discharge monitoring of IRIS POWER, especially the MCGUARD II equipment.

- Help customers effectively monitor equipment condition under operating conditions including partial discharge monitoring, rotor flux, busbar end vibration… Create a basis for economical maintenance and repair optimal cost and efficiency.

- S5T is always accompanied by the world’s leading team of partial discharge data analysts, and of IRIS POWER, always ready to support customers anytime, anywhere.

Professional working process from consulting, design, installation, transfer, to customer care.

For detailed advice on each periodical online PD monitoring solution suitable for plants, equipment… Please connect with us by sending a request to the mailbox, or contact us at the following address:

- Address: S5T Vietnam Technology and Solution Joint Stock Company.

- Lot B15, Duong Noi Resettlement Area, Duong Noi, Ha Dong, Hanoi.

- Tel: 0243 540 1858 – Fax: 0243 540 1859

- Email: info@s5t.com.vn