If the wedges are loose, the stator windings or guide bars can vibrate in the groove, leading to insulation wear and ground fault. In the long run, it will seriously affect the performance and reliability of electrical equipment. Iris Power’s SWA is the solution to this problem. It allows maintenance personnel to easily and efficiently assess the tightness of stator windings in motors or generators. Simultaneously measures, electronically stores and allows for easy, consistent testing of accurate trends in wedge tightness data.

What it means to install a SWA kit to monitor partial discharge (PD) conditions for equipment

According to the traditional method, the stator wedge will be tested for tightness by hammering the wedge and listening to the sound it makes. This approach is often slow and prone to inconsistencies. Therefore, measuring wedge tightness using the SWA electronic method will provide faster, more accurate results, and provide more consistent results.

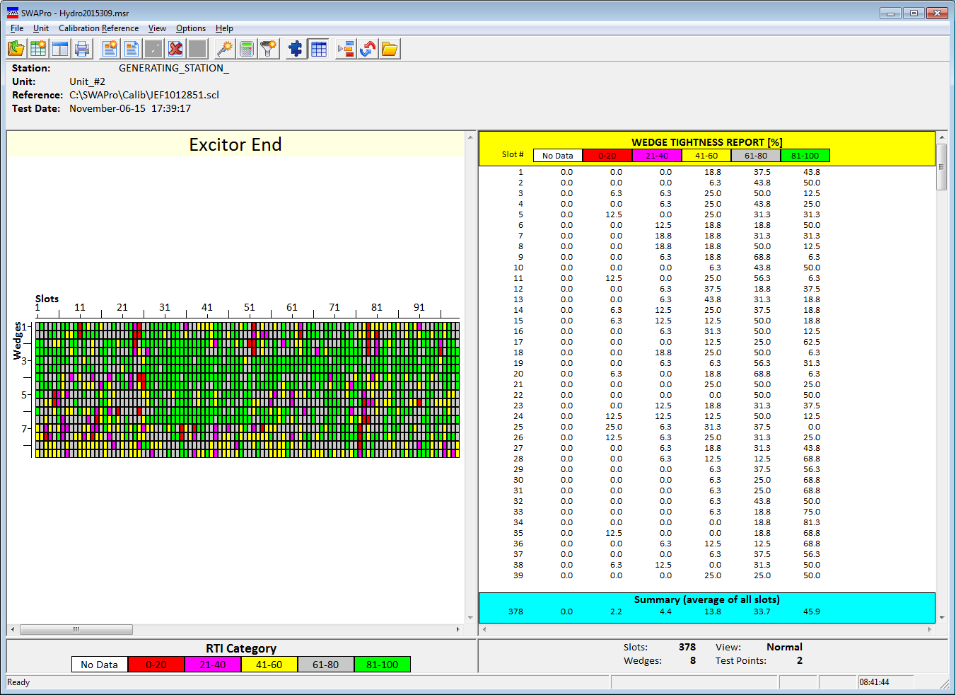

The Iris Power SWA instrument can be used to test most generator and motor stator slot wedges, including those with ripple springs. The handheld probe will automatically touch each wedge about 30 times in three seconds, the accelerometer collects the data then transmits it to the Iris Power SWA instrument. The final results are presented on the computer as numerical values and color-coded density maps.

Benefits of installing SWA wedge tightness analysis solution:

- Make well-informed maintenance decisions based on reliable and consistent SWA data.

- For use with all camcorders, including ribbed spring wedge systems.

- In standard test mode the tightness of each wedge is compared to predefined values while in advanced mode the tightness of each wedge can be compared to all other wedges in the roll wire, wedge of another coil or any reference selected by the user.

Numerical, objective, reproducible test data, eliminating the subjectivity of manual methods. - Quick and easy wedge tightness testing and analysis, permanent test data record, easy report generation, installation option on robotic vehicle to further automate the inspection process.

SWA system components for installation of electric motors, small generators, circuit breakers and isolated phase conductors

+ Hardware

The SWA instrument set includes: Hand-held probe and SWA data collector.

Handheld probe and SWA . data collector

Stator SWA . wedge tightness analysis solution

+ Software

SWA Pro software is used to configure monitoring modules, store collected data, view and trend data to monitor stator winding tightness.

SWA Pro software

+ Service

The service collects and analyzes data on the tightness of stator winding wedges, analyzes and gives reports to have a basis for building maintenance and repair plans with optimal cost and efficiency.

Procedure for implementing SWA . wedge tightness analysis solution

Step 1: Stop the machine, take the rotor out of the stator.

Step 2: Use a handheld probe and move along each stator guide.

Step 3: Collect data about the SWA kit and upload it to the software installed on the laptop.

Step 4: From the software, give the graphs and codes about the tightness of the wedges.

Why should you choose to install the Iris Power PD SWA monitoring system provided by S5T?

Why choose Iris Power’s PD SWA monitoring solution?

Overcoming the traditional methods, PD SWA solves the limitations and improves with superior functions. PD SWA measures wedge tightness electronically, giving results faster, more accurately, and providing more consistent results. The Iris Power SWA can even be used to test most generator and motor stator wedges, including those with undulating springs.

Why should you choose the PD system installation service provided by S5T?

S5T is not only an authorized dealer in Vietnam to distribute PD surveillance systems provided by Iris Power, but we are also an enterprise with full capacity and experience to bring customers the best solutions. world today:

- A team of experienced, well-trained experts with in-depth knowledge of partial discharge, has experience in construction, installation, configuration, testing and data analysis of PD in projects. such as: installation of a continuous online monitoring system at Dong Nai Hydropower Plant, periodic PD data collection and analysis system project at Air Liquid Vietnam, and many other projects)

- Capture, consult and build the optimal solutions for partial discharge monitoring of IRIS POWER, especially the MCGUARD II equipment.

- Helping customers most effectively monitor equipment condition under operating conditions including: partial discharge monitoring, rotor flux, busbar end vibration, … creating a basis for maintenance and repair in the most efficient and cost-effective manner.

- The team of experts analyzing partial discharge data of S5T and IRIS POWER always follow up with customers, ready to support anytime, anywhere in the form of online / offline..

- Professional working process from consulting, design, installation, transfer, support to customer care.

For detailed advice on each periodical online PD monitoring solution suitable for plants, equipment, etc… Please connect with us by sending a request to the mailbox, or contact us at the following address:

- Address: S5T Vietnam Technology and Solution Joint Stock Company.

- Lot B15, Duong Noi Resettlement Area, Duong Noi, Ha Dong, Hanoi.

- Tel: 0243 540 1858 – Fax: 0243 540 1859

- Email: info@s5t.com.vn