Currently, there are many products and solutions for online monitoring of transformer status. But to find a product that meets the market demand for efficiency and simplicity is not an easy thing. Therefore, S5T and Camlin Energy have combined and provided a TOTUS transformer monitoring solution in Vietnam. Through the installation and deployment, the success level of the product application has been shown in projects.

Transformer monitoring solution of TOTUS – Camlin Energy

Camlin’s transformer monitoring system includes the following monitoring technologies:

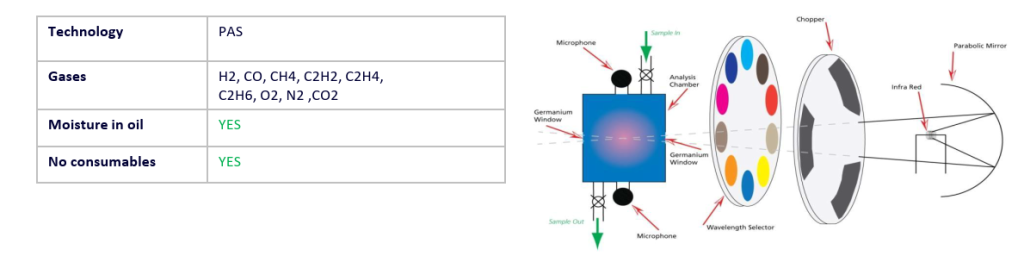

Monitoring of gas content in oil (DGA) using PhotoAcoustic effect (PAS)

Using photoacoustic analysis technology to detect gases in oil, this method can detect 9 types of gas dissolved in oil including oxygen.

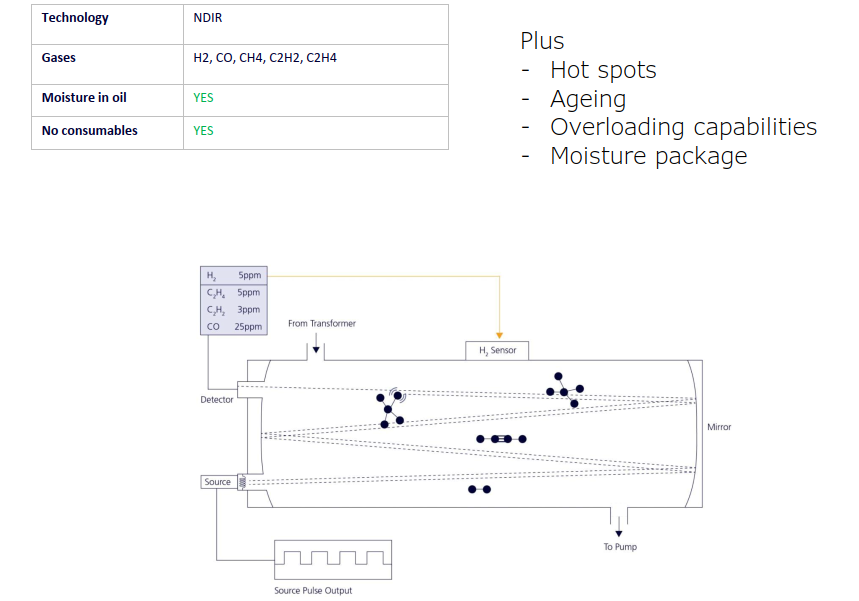

Monitoring of gas content in oil (DGA) using NDIR . technology

Using an infrared (non-dispersive) absorption sensor, the gas type and concentration can be detected by the infrared absorption spectrum of the gas and the corresponding absorption amount. This technology is commonly used to analyze 5 different gases.

Online partial discharge (PD) monitoring using Camlin triangulation and Tap adapter (Bushing Adapter) sensor

Tap adapters are designed to ensure safe and reliable installation with surge protection and effective noise reduction. Tap adapter continuously monitors to ensure all PD signals are detected. The data is then converted into a graphical form (PD Triangle) making it easy to recognize and distinguish the noise signal.

Monitoring of arcing through comparison of DGA and PD

Bushing monitoring includes monitoring for short circuit, dirt, dielectric loss (tan delta), arcing (Arcing):

Bushing monitoring uses a smart algorithm to eliminate false alarms, help detect errors that are forming early, and automatically separate the PD signal in the bushing. The solution for measuring the relationship between tan delta and bushing capacitance has high stability, is also easy to put into operation, does not need to be adjusted, does not need to be equipped with additional software.

Fault Current Monitoring (TFC)

Fault current monitoring records all fault currents through the transformer windings and evaluates key parameters to predict transformer winding strain. In addition, it can also evaluate the correlation between fault current with DGA, PD, Bushing measurement data.

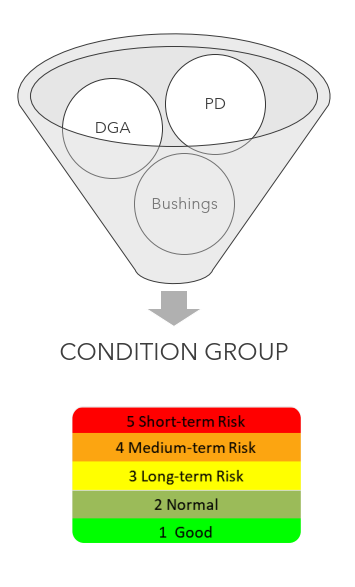

Camlin Energy’s transformer online monitoring solution includes the combination and calculation of bushing (Bushing), partial discharge (PD) and dissolved gas (DGA) monitoring. ) to make an overall conclusion about the condition of the transformer.

Components of the TOTUS transformer monitoring solution

- Monitoring cabinet: TOTUS Camlin Energy: The cabinet is placed as shown in the attached image below.

- Sensors: Bushing adapter (monitoring of bushings), current transformer (monitoring of fault current).

- Software: TOTUSPRO is equipped with tools for fault diagnosis analysis.

Application of transformer monitoring system in thermal power plants, hydropower plants and power transmission systems

All oil transformers in power plants and transmission systems can apply Camlin Energy’s TOTUS monitoring system.

Benefits of installing online transformer monitoring solution

- The system uses the same analysis software for all measurements, which increases the reliability of transformer condition assessment.

- Detecting and diagnosing problems at the earliest stage helps to minimize damage and prolong transformer life.

- The system is equipped with Embedded web server with powerful data analysis tools, helping users to manage information evaluation effectively.

- Integrated dissolved gas analysis (DGA) function.

- Ability to detect 9 different dissolved gases.

- Using photo-acoustic spectrocsopy (PAS) technology requires no calibration and carrier gas.

- Use a monitor for single-phase transformer sets.

Installation process of online transformer monitoring system TOTUS Camlin

- Step 1: Receive information from customers.

- Step 2: Conduct a survey to collect information about the existing system, the existence and needs of customers.

- Step 3: Provide preliminary design solution.

- Step 4: The design solution is approved by the investor.

- Step 5: Provide detailed design and approved by the investor.

- Step 6: Carry out installation, test run at the site.

- Step 7: Technology transfer training for customers.

Why should you choose to install the TOTUS online transformer monitoring solution provided by S5T?

S5T owns a team of experienced and knowledgeable experts who have participated in many practical projects such as: Equipping the main transformer monitoring system for Tuyen Quang hydropower (2018), equipping a monitoring system for the main transformer of Tuyen Quang hydropower plant (2018). monitor transformers for Song Ba Ha hydropower plant (2020), provide transformer monitoring system for Ban Chat hydropower plant (2021), upgrade transformer monitoring system for Tri An hydropower plant (2021) . Along with that, S5T engineers always follow the process, ready to support anytime, anywhere: remote support, live support in the field.

To receive more information about solutions/services and goods related to Camlin Energy’s TOTUS transformer monitoring system, as well as similar information, please send an inquiry to the mailbox, or contact we:

- Address: S5T Vietnam Technology and Solution Joint Stock Company.

- Lot B15, Duong Noi Resettlement Area, Duong Noi, Ha Dong, Hanoi.

- Tel: 0243 540 1858 – Fax: 0243 540 1859

- Email: info@s5t.com.vn