Today businesses are facing fierce competition from rivals. Changing workflows, people, and adopting new technologies are imperative trends to help businesses not fall behind. With the desire to help customers achieve international-standard workflows, thereby improving reliability, availability, and reducing operating costs, repair and risks, S5T has partnered with GE Digital provides APM asset performance management solutions for factories in Vietnam.

What is APM solution?

In the industrial world, asset performance management (APM) is the name given to the processes companies use to monitor, evaluate, maintain, and invest in the equipment (assets) that need it. necessary to help operate the business according to the set goals.

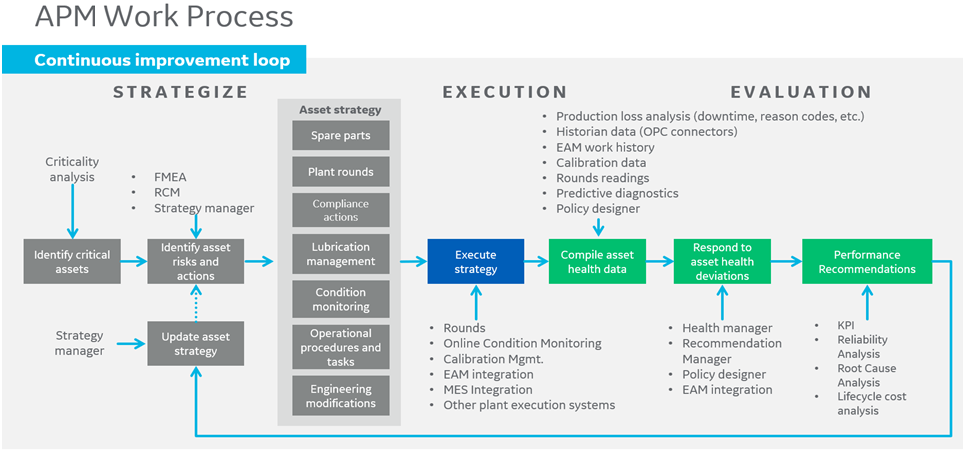

Workflows with GE APM

Analyze equipment criticality, identify risks and recommend corresponding mitigation actions. Asset strategies will then be executed through different systems, the results will be stored, evaluated, analyzed and counter-adjusted actions if necessary. This is a continuous improvement and self-contained process.

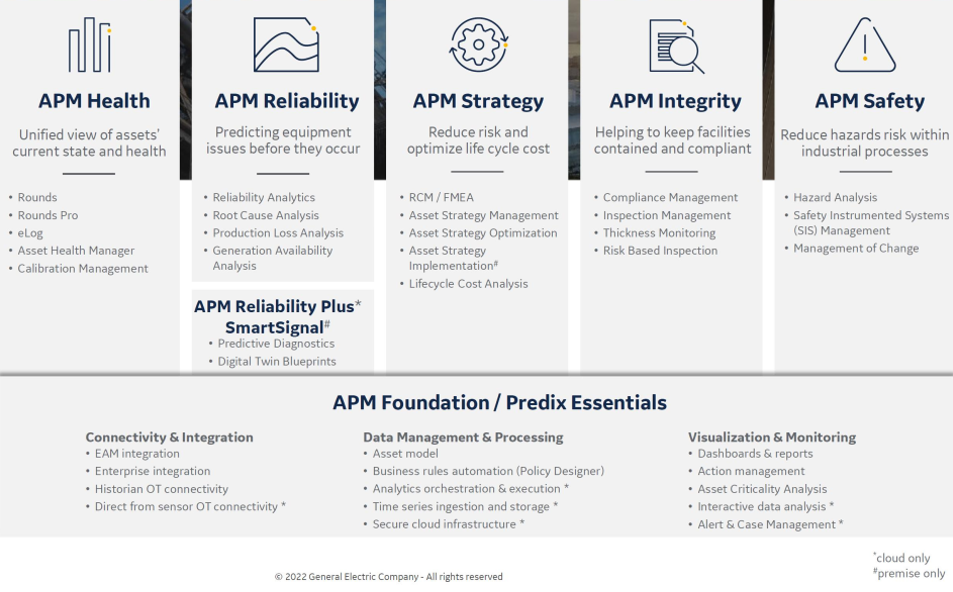

What does APM – GE asset performance management solution include?

GE Digital’s APM solution suite includes software modules aimed at solving various business problems.

Modules of APM software

1. APM Foundation

APM Foundation helps to connect data to different systems such as EAM, CMMS, Historian, ERP, MES, or data directly from sensors. Data will be managed and processed, then displayed and monitored through Dashboards, KPIs, reports according to user requirements.

2. APM Health

APM Health indicates the overall health of the property, providing early warning of potential failures and high-risk areas. This module includes the following main features:

– Rounds: tool to digitize field inspection activities.

– Asset Health Manager: Asset health management.

– Calibration Management: Device Calibration Management.

3. APM Reliability

APM Reliability predicts device failures before they happen. This module includes the following main features:

- Reliability Analytics: Provides tools that apply reliability engineering principles to help plants devise (short-term) and strategic (long-term) tactics for equipment maintenance and operations management.

- Root Cause Analysis: Determine root cause of problems using PROACT analysis methods (identify the right problem to solve – Problem, determine the desired goal – Objectives, understand the consequences of each alternative – Consequences, consider the trade-offs when choosing each alternative – Tradeoffs)

- Production Loss Analysis: Manage production targets by tracking events and impacts, and adjusting production losses.

4. APM Strategy

APM Strategy helps to reduce risk and optimize asset lifecycle costs. This module includes the following main features:

– ACA: Allows users to determine the importance of assets based on the worst-case scenario, thereby giving an overall importance.

– RCM:RCM facilitates the development of asset strategies that reduce the impact of functional failures from a system-asset perspective. By focusing on keeping systems up to standard performance, the result is a greater impact on production goals rather than focusing solely on the mechanical failures of individual assets.

– FMEA:Unlike RCM analysis focuses on preventing functional failures at the system level, FMEA is designed to identify and mitigate identified critical failure modes at the device level.

– ASM: The ASM provides a common methodology for identifying actions and mitigating risks for any asset, providing the ability to evaluate existing plans with basic, designed, qualitative risk analysis. Designed to be both simple and easy to use.

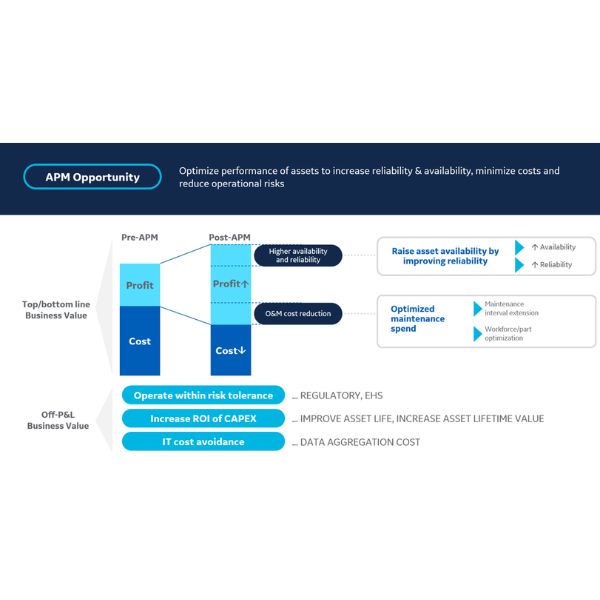

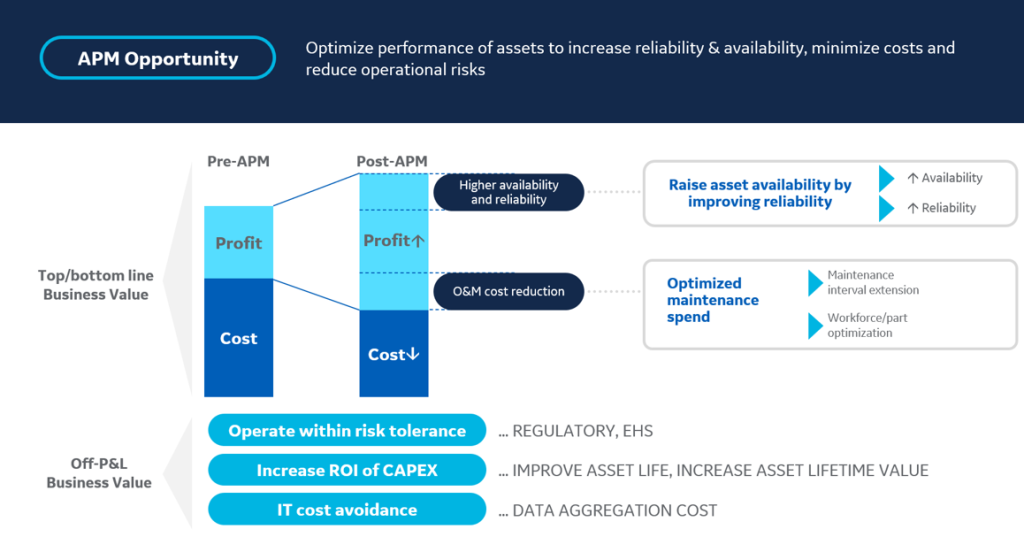

Effectiveness of asset performance management solution

- Increase asset performance – i.e. by leveraging predictive analytics, forced shutdown of assets is eliminated, thus increasing asset utilization, availability (decreased EFORd).

- Reduced reactive maintenance – predictive analytics allows unplanned repairs to be avoided thereby reducing interventions due to unplanned failures.

- Increase employee productivity – digital twin technology allows for immediate identification of degraded assets, thus eliminating MTTI (Mean Time to Identify) and reducing MTTK (Mean Time to Know) & MTTR (Mean Time to Repair).

- Increase reliability and availability of assets.

- Gain visibility for better decision making through a dedicated user dashboard and unified data views that provide operational insights to drive business results.

- Provides insights to reduce O&M costs by developing individualized visibility into asset downtime, O&M costs, repair times, asset health and processes working open/closed.

The effectiveness of APM

What industries can APM applications be applied to?

Asset performance management solution:

- Power plant.

- Oil factory.

- Chemical factory.

- Cement plants

- Steel factory.

- …

The process of implementing and installing the APM asset performance management solution of S5T sales agents

S5T is currently an authorized distributor of APM solutions by GE in Vietnam, providing customers with a standard process with the following implementation steps:

Step 1: Initiate and plan the project.

Step 2: Design & evaluate the solution.

Step 3: Connect and configure the system.

Step 4: Check and accept the system.

Step 5: Put the system into operation & support.

Step 6: Coaching & Mentoring.

Step 7: Training on software & methods.

To ensure the success of the project, GE and S5T recommend customers to use the APM Road Mapping service. Through this service, GE experts will come directly to customers to understand the actual needs and feasibility of the project. As a result of this service, customers will get a detailed version of the technical solution, implementation roadmap, people to prepare as well as the cost to implement the project.

Why choose APM – GE asset performance management solution provided by S5T?

- S5T is currently the only partner in Vietnam of GE Digital, a leader in APM asset performance management solutions.

- We have experience in implementing efficiency optimization projects, providing monitoring equipment for large power plants in Vietnam.

- The sales implementation process is fast and professional, ensuring on schedule, meeting customer needs.

- The company’s network of experts worldwide, including the Asia Pacific region, always accompanies S5T experts to support customers anytime, anywhere by online and offline form.

For more detailed information about the service, please send an inquiry to the mailbox, or contact us at the address below for professional advice:

- Address: S5T Vietnam Technology and Solution Joint Stock Company.

- Lot B15, Duong Noi Resettlement Area, Duong Noi, Ha Dong, Hanoi.

- Tel: 0243 540 1858 – Fax: 0243 540 1859.

- Email: info@s5t.com.vn.